Add Date: 2025/3/7 Views: 1

Keyword:Small five axis machining center,Small five axis linkage machining center,Desktop machining center, Teaching CNC machine tool,Five axis machining center

A machining center is a numerically - controlled machine tool with a tool magazine that can automatically change tools. Under the control of the CNC system, it can automatically select tools, adjust spindle speed and feed rate, and carry out multi - process part machining according to a pre - programmed program.

The CNC system is the control core of the machining center. By reading CNC programs, it controls machine tool movements. It can precisely control spindle speed, feed rate, tool selection, and cutting path.

Machining centers usually have manual control functions. Operators can manually control machine movements via panel buttons or a handwheel, such as for manual tool changing or feeding, which is useful during debugging or repair.

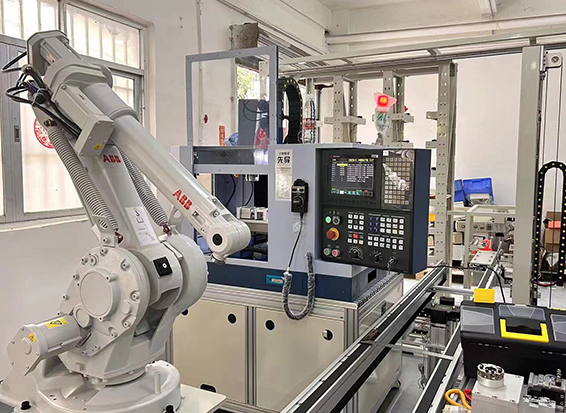

XENDOLL Small CNC Machining Center, Model: VMC220

Product Features:

1. Operated at 220V, it occupies little space, consumes less electricity, and combines transparent acrylic with sheet metal for safe - enclosed - structure observation and stability.

2. With a 4 - position automatic tool - changer (expandable to 6), it uses 0.6Mpa air pressure.

3. It has an industrial - grade CNC system for international standard programs, with auto - fault - detection - alarm and power - failure memory.

4. The three - axis tracks are covered by dust - and chip - proof bellows to protect the tracks and ball screws from wear caused by cutting fluid and residues.

5. The three - axis C3 - grade precision double - nut ball screws, after medium - frequency heat treatment and precision grinding, are pre - tensioned to reduce thermal deformation and ensure high positioning and repeatability accuracy.

Industrial CNC Machine System

1. Integrated cast - aluminum panel, oil - and water - resistant, with 8 - inch color LCD.

2. Max rapid speed: 60m/min.

3. 4 feed axes, 1 analog spindle. Parameters set start/stop speed and acceleration/deceleration time for drilling - milling machines, machining centers, etc.

4. Manual and handwheel modes use stepless speed control. Handwheel mode can be immediate - stop or full - run.

5. Enhanced file management and program editing for quick file preview, trajectory check, and efficiency boost.

6. System PLC: Open - architecture PLC with ladder - diagram display, real - time monitoring, and online editing.

7. Program format: ISO code. Supports macro - code programming, relative, absolute, and polar coordinate programming.

8. Program call: Supports parameterized macro - program calls, 4 - level sub - program nesting.

9. USB: USB file operations and DNC machining. Supports PLC program, system software upgrades via USB.

Machining centers are widely used in automotive parts processing, such as engine blocks, cylinder heads, crankshafts, and connecting rods. They enable high - precision, high - efficiency machining, meeting automotive industry requirements for part quality and production efficiency.

In aerospace, machining centers manufacture aircraft structural components and engine parts. Their high precision and reliability ensure strict quality standards for aerospace parts.

Machining centers can process mold cavities and cores. They can handle complex shapes and meet high - precision requirements, improving mold manufacturing efficiency and quality.

Welcome to our video link:

YouTube: Xendoll

Facebook: Xendoll

WEB:www.xendolltools.com